Understanding Asbestos

There are plenty of things we don’t want to think about in the hotel business. We don’t want to think about what happens in our stairwells. We don’t want to think about how dirty your hallway carpet gets when it’s been raining outside.

Hotel construction is no different. Hotels requiring renovations are generally old buildings, and old buildings have skeletons. I implore you though – If you’re in one of these buildings, you must know about asbestos.

Asbestos is a compound that has been mined and used for thousands of years. On the surface, it’s a miracle material: it’s sound absorbent, an outstanding insulator and extremely cheap. As such, manufacturers, builders and safety clothiers used it everywhere.

Unfortunately, it’s hazardous.

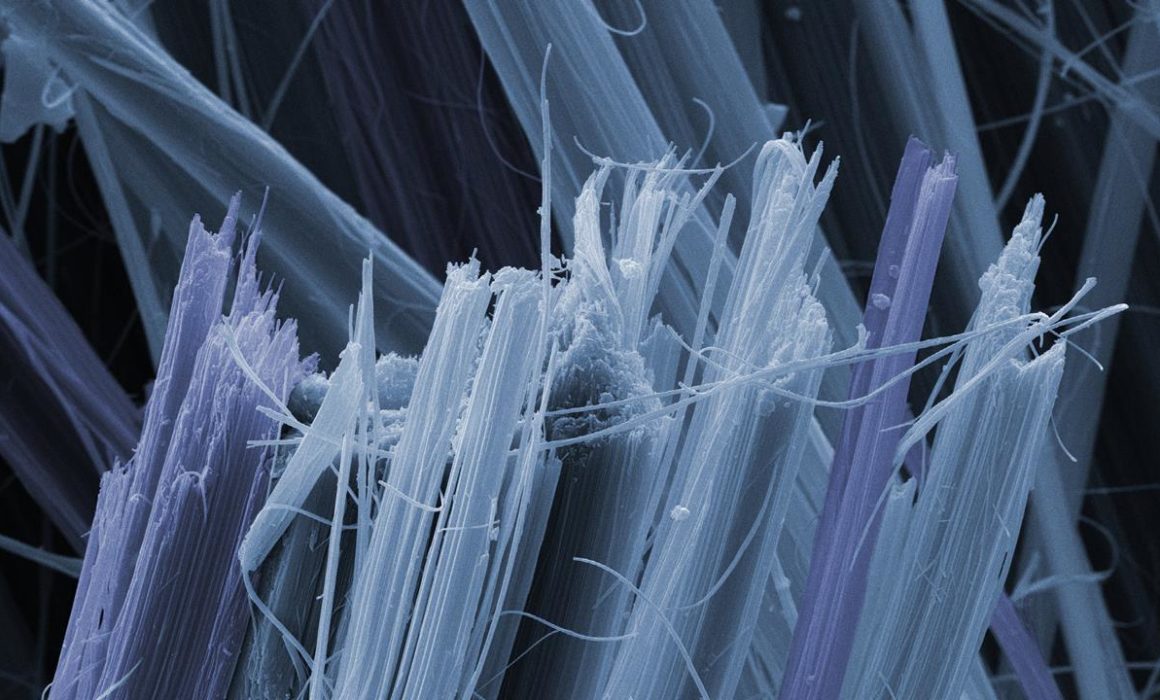

Asbestos is fibrous and breaks down easily. Those asbestos fibres, when inhaled, cause inflammation and scarring in the lungs. Long term exposure can lead to numerous serious and fatal illnesses: a variety of cancers – including mesothelioma and lung cancer, COPD, thickening of lung canals and reduction of lung capacity. These issues began to be identified in the 1800s but no actions were taken to restrict its use in the United States until 1973. Even still, asbestos has not been banned completely.

Asbestos excerpt – ‘Annual Report of the Chief Inspector of Factories and Workshops for 1898: Part II: Reports’.

Now – I’m not saying rip apart your hotel looking for it. Quite the opposite. Undisturbed asbestos poses little threat. Asbestos fibres are released into the air during degradation, damage and disruption of asbestos containing materials. Knowing is what’s important.

We strongly suggest the following:

1) Identify potential problem areas

Asbestos was used in hundreds of different materials within hotels, but some common items to be aware of (a more comprehensive list can be found here:

- Any plaster applications – especially walls and mortar

- Mechanical equipment, especially those from before the 1980s

- Insulation throughout the property especially around turns, joints or elbows (it will feel especially hard to touch) and within block walls (gravel-looking substance within the cavities of hollow block walls)

- Drywall and drywall mud applications, especially those from the 1980s and earlier

- Floor and window levelling compounds

- Roofing felt

- Small 9” vinyl floor tiles

2) Get it professionally tested

Educate yourself. Hire an environmental engineer to assess asbestos risk prior to starting work. Test the areas that you’re asking contractors and staff to disturb. Testing costs money, but the liability of a negligence claim is even more expensive. Not knowing is not a defence.

Bring in the experts!

3) Follow a designated asbestos working environment plan, encapsulation plan and/or abatement (removal) plan

You have three broader options to manage ACMs in your property – a good engineer/consultant should explain all three and make a suggestion on any one or combination of approaches.

a) Abatement/Removal

Pretty straightforward. You have asbestos, bring people in to remove it. When possible, it’s the safest solution.

Keep in mind though – this can cause significant business interruption and put your staff and guests in more danger if the ACMs being removed are difficult to access, cover a large area or require extensive demolition of ‘good’ material to get to.

Removal is certainly ideal but isn’t always the safest option.

b) Encapsulation

‘Encapsulation’ refers to limiting most or all contact with ACMs by covering or hiding them to prevent disturbance or deterioration. Encapsulation can include things such as:

- Placing a new plywood subfloor above asbestos containing vinyl tile and/or leveling compound

- Covering an asbestos plaster or ‘mudded’ wall with another layer of drywall on top of it.

- Installing an acoustic tile ceiling inches below the existing ACM containing ceiling

- Completely restricting access to mechanical rooms that have significant amounts of asbestos.

A skilled contractor and strict process is required to install materials over ACMs. Areas being disturbed must remain slightly damp (the asbestos fibres attach to water particles to prevent fibre release into the air). Require your contractor to specifically acknowledge – either within a purchase order, waiver form or executed notice – that asbestos is present on site and their commitment to ensuring safety precautions are mitigated. Have an engineer present to monitor air quality during and after work is complete. Most importantly, once the work is done, compile logs and a map of all work done, precautions taken and all contractors and engineers on site during the work.

c) Strictly follow working plans and procedures for working around asbestos

Ensure that your environmental engineer prepares a working plan and that those most vulnerable – especially maintenance (given that they are frequently tearing things apart and rebuilding them) understand and acknowledge it. Formal training is readily available throughout North America – your local construction association can point you in the right direction. Trained maintenance can protect your staff and guests best. Also, critically, ensure that all employment contracts include reference to the asbestos on site, their locations and procedures for new staff to review and sign.